Summary

Written for:

- Warehouse Automation Manager:

To oversee and execute security operations, guarantee effective and safe warehouse equipment utilization.

- Operations Specialist:

Can look over the business plans, handles the organizational workflow, and shape up the day-to-day warehouse movements.

- Business Strategist:

Build an internal standard to accomplish the annual goals, oversees the workforce. Initiates strategic and cost leadership design for the organization’s improvement.

Introduction

Benefits of having precise dimensioning information in the warehouse

- Increased shipping cost accuracy

- Improved slotting and cartonization

- Enhanced future storage planning

- High-level quality control

Three imperative Characteristics of a Successful Dimensioning Program

Process Design That Works

Integrated Systems and a Data Strategy

If you’re unfamiliar with automated dimensioning, there is a high chance that you might think of dimensioners as innovative equipment that calculates the dimensioning details of parcels and freights efficiently and accurately. Although this is real, they will potentially do a lot more if you’re willing to take advantage of them.

A Well-Informed Workforce

Conclusion

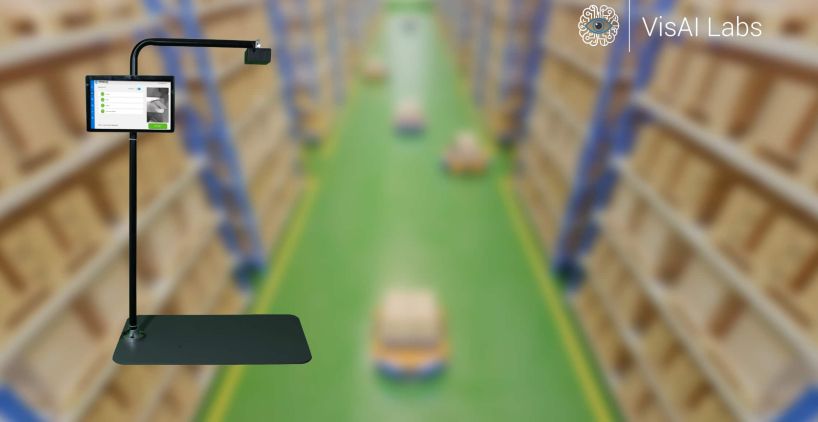

Adding intelligence to your dimensioning with vMeasure Parcel pro- automated dimensioning system

In warehouse and distribution centres, the primary pitfall of measuring parcels and pallets by hand inaccurate measurements and transpositions. Understanding this, VisAI Labs has built a vMeasure Parcel Pro automated dimensioning system to capture the dimensional information like length, breadth, width, and height of various size parcels in a second. These automated dimensioners come in two types: Parcel and pallet dimensioners.