Summary

The world of logistics and supply chain increasingly driven by various technologies such as Artificial intelligence (AI), computer vision, and Edge AI. The warehouse continues to embrace technology to revamp the operation entirely by automating the processes to optimize the supply chain and decrease order fulfillment expenses. To transform warehouse to automation, you need to understand the business workflow, which helps choose your vertical the right technology.

Customer persona

- Logistics Specialist: sketch and optimize flexible transportation, logistics, warehouse, and customer services by understanding the latest warehouse technology trends.

- Operations Specialist: determines the storage requirements to manage various processes like inventory management, shipping, and evaluating policies and procedures to improve the warehouse operations using automation.

- Business Strategist: take responsibility for developing various strategic plans to reach the organizations’ goals and targets. Also, analyzes the existing operational strategies to improve profitability in the warehouse.

- Warehouse automation manager: maintains the statistical and financial records, ensures the quality and deliveries, and understand the latest technologies to optimize the working pattern in the warehouse.

Deploying automated dimensioning systems to the warehouse industry

Does it seem like you’re hearing a lot about dimensioning systems these days? From Amazon to Flipkart and every e-commerce platform in between, parceling is an inherent part of the delivery process. While e-commerce has been gaining traction for a few years now, the Covid-19 pandemic has only accelerated this demand. With customers sheltering in the comfort of their homes, online purchases are at an all-time high.

With this growing demand, warehouses and DCs need to invest in providing precise dimensions for all of their goods and deliveries. This dimensional data is essential for package shipments to measure delivery costs and choose the perfect carton correctly.

Dimensional data will help users measure just how much space a load would take in the pallet shipment trailer.

Although you could send an employee over to record the height, width, and length of each package or carton using a tape measure, that technique is time-consuming and vulnerable to error. And while digital tapes are more accurate, they’re also very labor-intensive. For these reasons, it makes sense to invest in an automated dimensioning technique that requires little to no human involvement.

It helps to know your choices when you start looking at dimensioning equipment and which type would work best for you.

Dimensioning systems usually fall into two main categories: systems utilized to measure pallet loads and systems utilized to measure parcels or individual items. Parcel dimensioners can be further broken down into two types of units: static tabletop dimensioning systems and in-motion systems that weigh objects as they travel through a tunnel.

With a range of dimensioners, it could seem challenging to pick the right one for you. We’ve curated a list of the different dimensioners’ advantages and disadvantages to help you out.

Pallet Dimensioners

A pallet dimensioner is used to measure a pallet load’s precise volume before it’s mounted in a trailer. The pallet to be measured is transported by forklift to the system, where it’s inspected and dimensioned. For trucking companies looking to estimate delivery costs, pallet dimensioners are a good option depending on the precise volume a load takes up in the truck.

They also offer a means for shippers at the end of the month to prevent freight-charge shocks and gather data useful in settling carriers’ disputes.

Pallet dimensioners, with all their advantages, still have their limitations. Perhaps the most significant drawback of using these machines is that it’s a little cumbersome to pick up, transfer, and scan pallets.

Parcel/Package Dimensioner

Parcel/Package dimensioning systems are now present in both static and in-line types.

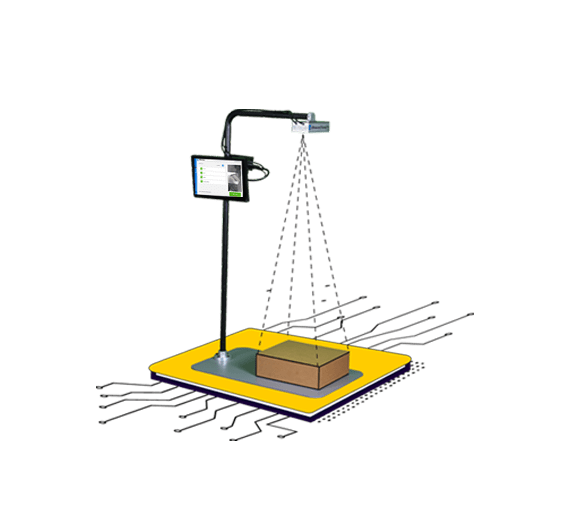

The static dimensioning method is a “semi-automated” approach. An operator puts a parcel or object on the dimensioning system, and then the system calculates (and also weighs) the parcel. The machinery may be stationary or mounted on a cart and wheeled around the distribution center.

By comparison, when it comes to an in-line/in-motion or dynamic dimensioning system, a box or parcel goes down a belt. It travels through a tunnel, where either a 3-D camera or laser sensors capturing its measurements. These tunnels are typically installed after pick and pack stations and before shipping and labeling stations.

At the outbound end of distribution centers, either static or in-motion dimensioners can capture dimensional data required for estimating shipping costs. To measure how much storage space the object would need or determine what size of the carton to use for shipment, they’ll also be used at the inbound end of a facility to obtain the measurements of stock-keeping units (SKUs).

Static vs. In-motion dimensioners

Compared to static dimensioners,in-motion parcel dimensioners are usually more straightforward and ideally suited for high-throughput operations. For operations that ship out 700 cartons or more per day, in-line systems are good.

In many situations, these tunnels function not only as dimensioners but also as in-line inspection points that record the weight of the carton, bar code, and other details dependent on text. At that stage in the handling process, some also take photographs of the package and record its status. For pick confirmation or defect identification, systems with these capabilities may be used before an outbound package or parcel is put in a vehicle.

In-line devices are usually costlier than static systems, but they’re becoming more affordable with advancing camera technologies.

Conclusion

Now with this information, you should be able to decide which dimensioner works best for you. And once that’s done, it’s time to start assessing the products of various manufacturers. Take different systems and measure them side by side using the same kinds of parcels or loads you manage in your everyday operations. Measure and test it for yourself before deciding to pick it up for your warehouses or distribution centers.

At VIsAI Labs, we’ve got a range of dimensioners that you can test out and try for yourself.