Summary

- Quality control, involving several components, is crucial to logistics operations.

- Automation in logistics reduces the scope for human error in QC while aiding in increasing the scale.

- Leveraging predictive maintenance helps significantly mitigate costs and time consumption.

Written for:

Warehouse owners, supply chain decision-makers, and anyone looking to improving logistics operations through quality control.

Introduction

Artificial intelligence and machine learning have reshaped several industries, including logistics. There are several facets to this transformation. Warehouse automation, predictive analysis, and automated dimensioning are some of the areas that have significantly leveraged these technologies to augment operations. These fronts provide substantial proof for the feasibility, efficiency, and economic milage that AI brings to the table for logistics. On this note, quality control is another area where AI has been working wonders for logistics operations

Optimized consumption of time, scalability, improved returns on investment, and feasibility are some of the fundamental tenets businesses must consider while adopting technology. It naturally follows that these factors must combine to enhance the quality of products, services, and experiences that bring them to the customers. Considering the benefits that it brings to the table, quality control is an important area that logistics should look to automate.

What is quality control in logistics?

Quality control in logistics extends efforts to detect defects such that operators can ensure consistent adherence to specifications and standards meeting customer requirements. This includes following inspection guidelines and controlling any issue that might arise in quality. Overall, it refers to the processes and efforts that eliminate the chances of errors, thereby improving cost-efficiency and the quality of products and services.

Consequently, quality control for logistics expediates the pace at which a product goes to market, enhances visibility and customer relations while simultaneously mitigating the loss of productivity with higher availability.

There are several examples of how the logistics industry can use automation to its advantage. For one, automated quality inspection enables the identification of defects in parts and finished products. Similarly, it can bring greater efficiency by automating tracking and documentation of product quality. Further, automation can reduce manual intervention and associated possibilities of errors in quality checks, consequently increasing the scale and scope of quality inspection. Enabling preventive maintenance, in turn, can again lower costs.

What is Nvidia DeepStream? How can it help?

Nvidia DeepStream is a flexible and scalable software development kit (SDK) with the components for rapidly prototyping AI solutions from Edge to Cloud. On a case-by-case basis, the SDK can be customized at different levels to build solutions that are apt for the particular use case. Developers can use this to plug in existing models or find sample pre-trained models that work best for the required application.

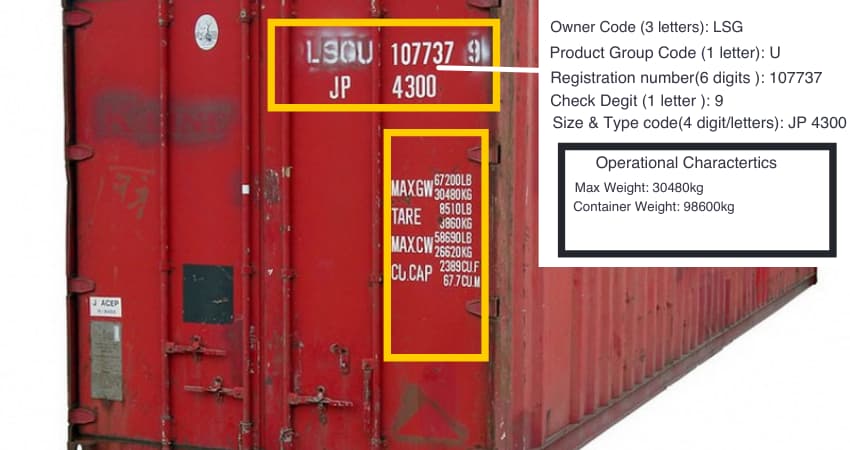

It is the customization factor that would enable us to use DeepStream to your advantage in quality control. When the model is customized as a detector, the AI will help accurately identify container attributes crucial for ensuring quality control in real-time. For example, the model can detect several container attributes, including type, name of the container, license plate number, payload weight capacity, and any damage to the container. Further, DeepStream comes with the option to integrate classifiers to run on detected objects. These trained classifiers can enable the collection of any inference that might specifically be required for your logistics processes. Thus, based on the information that one needs to extract for quality assurance, custom models can be trained and deployed on a primary detector on DeepStream.

Conclusion

An article published in the Harvard Business Review and quoted by McKinsey & Company in 2019 estimated supply chain management to be the industry that would be most impacted by businesses adopting AI. Accordingly, it predicted that the influence would create anywhere between US$ 1.2 trillion to US$ 2 trillion for firms in the sector worldwide. Of this, leveraging predictive maintenance would create about US$ 0.5 trillion to US$ 0.7 trillion, majorly from mitigating costs as much as from creating additional revenue. These numbers indicate that the adoption of AI is a crucial addition to the technology artillery of logistics operations everywhere.

At VisAI, we work to make these and more applications possible by leveraging artificial intelligence and computer vision advancements for Edge. The hardware capabilities and expertise we have combines with our engineers’ deep technical astuteness to craft cutting-edge solutions. Designed to save you costs, they simultaneously optimize the quality of your operations.

To know more about how we can optimize quality control for your logistics, get in touch with us at sales@visailabs.com.