Summary

Owning and running a retail space can often be very expensive.

Optimized use of space and product placement are known to promote better sales.

This blog discusses compliance to an automated planogram can help keeping an efficient eye on managing shelf stock and gaining more sales.

Written for:

Retail space owners, managers, and planners looking to optimize the use of retail space and boost revenue will benefit from this blog.

Is a well-stocked retail shelf the perfect picture of orderliness?

Well, the chances are that it isn’t. If you have ever wondered about the rationale behind the arrangement of a store shelf, you have probably thought of a few hundred possible combinations for putting these products on display. For instance, it would go without saying that you wouldn’t want to put chocolates on the top rack, nor would you like to put just chocolates on the most accessible lower shelf if they aren’t among the most sold items of your brand. Further, all this planning needs to agree with the historical sales data and awareness of your consumers’ psychology. A meticulously thought out planogram, kept in line with the concerns we have discussed above, would be your golden key to optimize your shelves in this aspect

But first, what is a planogram?

A planogram is a visual representation of the placements of products in your store. This can be used to optimize product placement for maximum sales.

Having a planogram chalked out by itself, however, doesn’t carry much weight. It is imperative to put it into active use. But shoppers’ interaction with the shelves might mix up product placement, leading to unnecessary inventory disruption without the prompt replenishment of racks. Even under the observant eyes of a sales representative in the store, things could go intensely haywire due to the magnitude of minute details that need tending to.

Here’s how automation, empowered by computer vision, proposes a befitting solution to the dilemma by enabling real-time supervision of product placements:

The installation of a camera best suited for your retail environment captures streams for the detection algorithm. The algorithm, in turn, detects the multiple SKU instances of particular brands. This is then corroborated with the planogram to identify discrepancies. In the event of a discrepancy, the system sends a real-time update to the sales representative in the store.

Sounds simple? Well, it is, unless your system is not able to tackle some key issues that might crop up in the process:

- The shelf images retrieved by the camera are not occlusion free as shoppers would constantly cross by the shelves. Elimination of this event from the stream is necessary for optimized detection.

- The model should be able to handle changes in illumination on the product or shelf.

- The items on the shelves remain symmetrical before and after replenishment due to a discrepancy. The automated model should be able to distinguish this change accurately.

A robust model in tackling these scenarios will consequently reduce the person-hours needed for the task and human errors in the process to a significant extent.

What can automating planogram compliance do for a store?

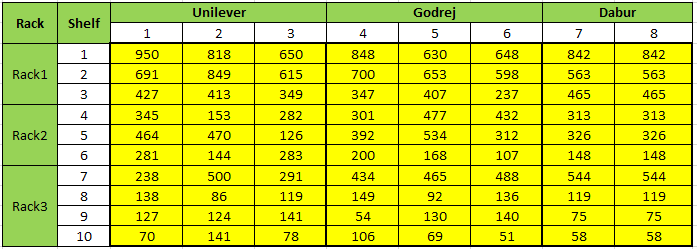

Let us begin by looking at this table:

The information provided here quantifies a product’s contribution to sales. As we saw earlier, any change in the product placement across the store could bring notable changes to this information.

In this light, automated, timely updates passed on to the sales representatives in the store could mitigate not just your customers’ displeasure at finding something they need going out of stock but also ensures that you don’t lose out on ensuing sales. Recent research funded by P&G has revealed that a 10 per cent change in planogram compliance can result in a 1 per cent change in the level of out-of-stocks that add to lost sales. The study also points out that of the customers who cannot find the product they are looking for, 31 per cent will purchase the same from a competitor, 15 per cent will delay the purchase, and 9 per cent would give up on making the purchase altogether.

Monitoring the impact of planogram compliance and tracking success or failure rates can help better plan during the reset cycle. Further, automated planograms can also ensure that checkout data agrees with the updated product count retrieved from the product image, providing proofing against theft or other malpractices.

Conclusion

Retail spaces can often cost a dear sum to function and maintain. Automated planogram compliance can ensure that the retail space is utilized optimally and arranged to craft a shopping experience your customers will love to bank on.

VisAI Platform – Human/People Detection Solution

Businesses today find themselves at a crucial juncture to adopt intelligent technology solutions that can optimize resource consumption while substantiating revenue.

VisAI Labs understands the need for Edge-optimized algorithms that meet various use cases to help retail businesses thrive with automation. To know more about how you can leverage automation in retail for your stores, get in touch with us at sales@visailabs.com.